Evaporation process

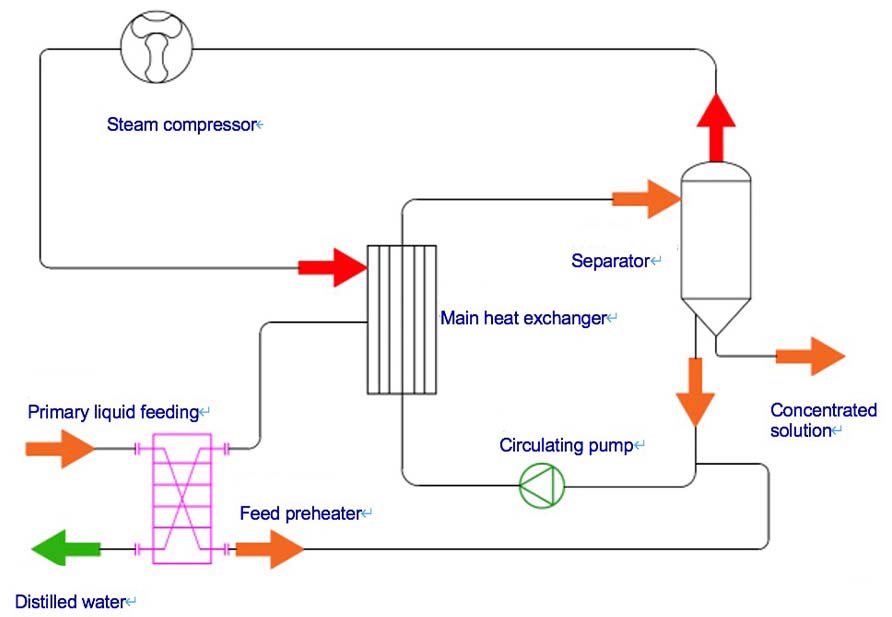

1- The MVR (Mechanical Vapor Recondensation) evaporator is a very efficient and low-consumption device for evaporation and condensation, which mainly works with electricity and saves a lot of energy. This device compresses and heats the produced secondary steam to increase its thermal energy and uses its latent heat to reheat the liquid in the evaporator, which results in concentration, desalination and COD removal. Except for the initial heating required during start-up, there is little or no need for additional auxiliary heating during operation. Distilled water produced after secondary steam heat exchange is recyclable and no additional steam discharge is required.

English